Mdf Cutting

MDF Cutting

Use a sharp, fine-toothed blade designed for cutting wood or MDF. A blade with a high tooth count will produce cleaner cuts When cutting MDF, it's generally best to use a slower cutting speed. This helps prevent chipping and splintering, resulting in a smoother finish After cutting, you may need to sand or finish the edges of the MDF to achieve a smooth and polished final result

Turn MDF into Amazing Wood carving Projects with Capable Tools

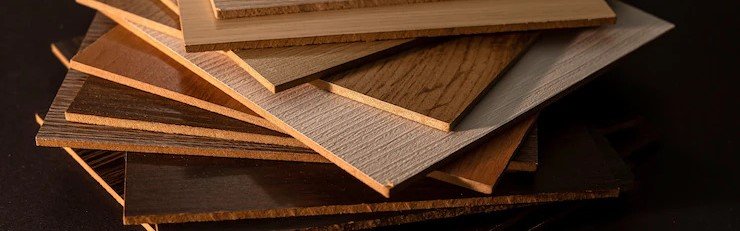

Medium Density Fibreboard (MDF) is an engineered wood-based sheet material made by bonding together wood fibres with a synthetic resin adhesive. MDF is extremely versatile and can be machined and finished to a high standard. Medium-density Fibreboard is a high-density material made with resins and wood fibre. It is made by pressing wood fibres embedded in a synthetic resin binder together. Apart from being inexpensive, they are ahead in qualities like strength and durability too. Therefore, MDF is suitable for a wide range of woodworking tasks, including furniture, cabinets, doors, and many other interior design applications.

MDF can be cut with any instrument that cuts wood; however, the cutting tool should be chosen by keeping the MDF's unique qualities in mind. But precaution must be taken to use the best tools to get the best out of it.

The easy and effective way to cut the MDF is using a table saw with a carbide-tipped blade. To avoid dust build-up, the blade should be carbide-tipped, and the table saw should have a vacuum removal system.

MDF produces smoke in the cutting process which must be removed quickly, to avoid staining. Removal of the smoke requires air assistance and lenses/optics to be checked for contamination. Adequate extraction should be used, to clear the smoke quickly. Smoke from some brands of MDF can contain toxic formaldehyde released by the adhesive component. Selection of the adhesive grade is only practical in Europe and to a limited degree in the US, as production is highly regionalized and not all plants have switched to low-toxicity adhesives. Use of low- or zero-formaldehyde MDF is therefore recommended. MDF is sensitive to cut conditions. Excess power, lower feed rates, excessive single-cut depths, and mistaken setting of the focal length of the machine optics can all result in burned and badly stained cuts and extensive heat-affected zones (HAZ) beyond the cut. As a starting point for test cutting, be careful to set the focal length of the optics according to the manufacturer's specifications.

List of service benifits

MDF has a uniform density and composition, providing consistent results in terms of texture and carving depth

MDF has a smooth surface that allows for precise carving details. It is free from knots or grain patterns found in natural wood, providing a clean canvas for intricate designs

MDF is available in various thicknesses, providing flexibility for different carving applications. Custom thicknesses can be achieved by laminating multiple layers if needed.

MDF is known for its smooth surface, making it an excellent choice for projects where a flawless finish is essential. Our cutting services ensure that the edges are clean and smooth, ready for finishing touches like painting or veneering.